Fire Testing of Structural Insulated Panels (SIPs) Construction

Article Index

SIPs Industries conducted fire tests on the SIPs to determine variables such as flame spread, roll-over and breach.

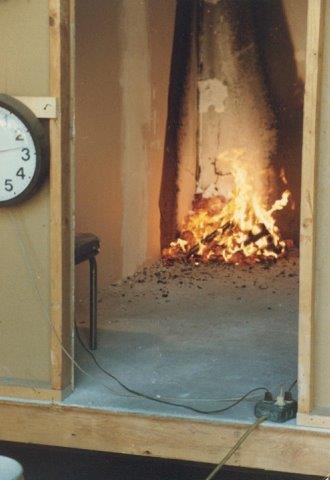

Fire is ignited in the corner of a SIPs building.

Fire is ignited in the corner of a SIPs building.

Corner Room Burn Test of SIPs

EPS SIPs wall and ceiling covered with standard ½ inch gypsum board having a 15 minute thermal barrier index.

15kg of wood crib is ignited in the corner.

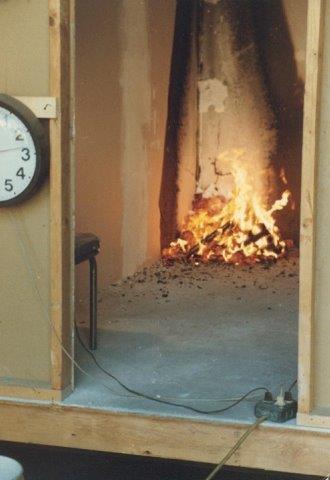

Blazing fire in the corner of SIPs building

Blazing fire in the corner of SIPs building

Corner Room Burn Test of SIPs

Wood crib is allowed to burn freely for a minimum of 30 minutes.

The test is run to determine:

- 1. flame spread

- 2. flame roll-over

- 3. flame breach into the wall

- 4. structural serviceability after a fire event

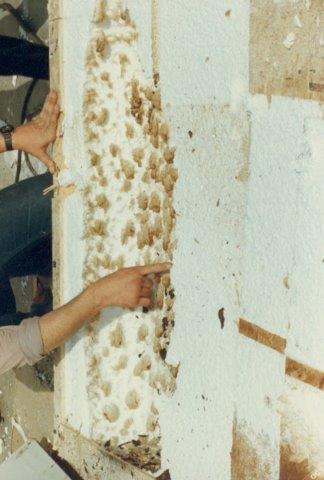

Post examination of the corner

Post examination of the corner

Corner Room Burn Test of SIPs

Post examination of the wall and ceiling showed no flame spread, no flame breach of the wall, no roll-over event, and the structural capability of the wall and roof/ceiling remained intact.

Localised scorching of the EPS SIP OSB interior structural skin

Localised scorching of the EPS SIP OSB interior structural skin

Corner Room Burn Test of SIPs

Removal of the ½ inch gypsum board showed localised scorching of the EPS SIP OSB interior structural skin.

Localised shrink back of the EPS core

Localised shrink back of the EPS core

Corner Room Burn Test of SIPs

Removal of the OSB skin showed localised shrink back of the EPS core and caramelized EPS demonstrating the effectiveness of the EPS flame retardants.

Burn Test of SIPs Wall

The mounted SIP wall

The mounted SIP wall

Mounting the SIP wall

Mounting the SIP wall

Burn Test of SIPs Wall

EPS SIP at 6½ inch are covered with 5/8 inch gypsum board.

The EPS SIP detail for surface spline connection was tested requiring two layers of gypsum board on the EPS SIP face.

A 9 foot high by 12 foot long EPS SIP wall section is mounted on a frame, 12,000 kgs of load is applied along the top of the EPS SIP wall section.

The wall section is mounted to a Fire Furnace

The wall section is mounted to a Fire Furnace

Burn Test of SIPs Wall

The vertically loaded EPS SIP gypsum board faced wall section is mounted to a Fire Furnace where 100% of the wall face is subjected to fire flame.

Temperature at the wall surface is maintained at 1000 degrees celcius for 1 hour.

Thermocouple rods are used to insure flame front at 100% of the wall surface at temperatures equal to or greater than 1,000 degrees celcius.

The vertically loaded EPS SIP gypsum board

The vertically loaded EPS SIP gypsum board

Burn Test of SIPs Wall

The vertically loaded EPS SIP gypsum board faced wall section is removed from the Fire Furnace after 1 hour of flame exposure.

Flame exposure side of the vertically loaded EPS SIP gypsum board faced wall section shows complete calcification of the gypsum board.

The vertically loaded EPS SIP gypsum board

The vertically loaded EPS SIP gypsum board

Burn Test of SIPs Wall

Immediately after removal from the Fire Furnace the EPS SIP wall section is subjected to a 30 psi cold hose stream over the entire face of the wall section

The wall is still under a vertical compression load of 26,400 lbs.

30 psi cold hose stream over the entire face of the wall section

30 psi cold hose stream over the entire face of the wall section

30 psi cold hose stream over the entire face of the wall section

30 psi cold hose stream over the entire face of the wall section

Burn Test of SIPs Wall

Hose stream spray continues, stored heat within the gypsum board causes steaming of water from the hose stream

Gypsum board continues to fall from wall surface due to high pressured hose stream.

Gypsum board continues to fall from the wall surface

Gypsum board continues to fall from the wall surface

Burn Test of SIPs Wall

This test is conducted to determine the structural durability of the wall under 3 storey loading after 1 hour of extreme fire exposure.

Post examination showed the SIP OSB skin and EPS attached and intact.

Post examination of the SIP OSB skin

Post examination of the SIP OSB skin

Burn Test of SIPs Wall

Close up examination of the structural lamination of the SIP OSB skin and EPS core showed all components to be intact and structurally serviceable.

30 minute fire test of SIPs wall

30 minute fire test of SIPs wall

Burn Test of SIPs Wall

30 minutes burn test

60 minute fire test of SIPs wall

60 minute fire test of SIPs wall

60 minute fire test of SIPs wall

60 minute fire test of SIPs wall

60 minute fire test of SIPs wall

60 minute fire test of SIPs wall

60 minute fire test of SIPs wall

60 minute fire test of SIPs wall

Burn Test of SIPs Wall

60 Minute Burn Test

Watch the SIPs Fire Test Presentation

Watch the video presentation here.