Comparison: SIPs Vs Other Building Products - Part 2: Timber Frame

Part 2 of our comparisons looks at Timber (Stick) Frames. Timber frame construction is common on the eastern states of Australia, and throughout the world.

It is a renewable material with fantastic construction properties and is the main structural material for buildings aiming to be highly energy efficient.

This building method is cost effective, lightweight and durable, but there is much criticism of Australian building guidelines and control for timber frame structures..

Timber

Timber being used as a building has been around for thousands of years, but the current detailing is going to cause building and possible health issues in the future.

The issue with timber frame construction in Australia will become more apparent in the years to come, as it seems little or nothing has been learnt from New Zealand’s leaky homes crisis in the 1990’s.

Ventilation

The New Zealand crisis wasn’t that long ago, and it wasn’t that far away from Australia, yet there is still detailing happening in Australia that allows claddings to be directly fixed to timber framing, with foil sarking and insulation directly behind. This leaves no ventilation space for vapour to escape and can cause moisture to build up behind the cladding.

Breathable membranes are becoming the norm in framed construction, which are by no means a bad thing; however, breathable membranes are no good if they can’t breathe.

A quick Google search to one of the major fibre-cement sheet cladding suppliers offers their installation guide. This method shows a vapour barrier outside the framing studwork, and Fibre cement sheeting applied directly over this.

There is no mention of insulation (a BCA requirement) which would fill the space between the studwork.

Moisture

When air is pushed through the structure due to pressure differences inside and outside the building, the vapour in the air will turn to moisture and build up behind the cladding due to a drop in temperature (dew point - where a lower temperature of a substrate causes vapour to condensate) or any other reason for moisture such as a water leak, etc.

The vapour/moisture should be allowed to evaporate away, but with the cladding fixed directly to the studwork over the membrane, there is no airflow or allowance for the moisture to escape.

Mould is caused by moisture build up with no air movement, insulation will be less effective and degrade when wet, and timber that is subject to prolonged moisture is prone to wet rot.

Correct detailing would allow for a batten outside the breather membrane, allowing air flow behind the cladding, and thus allowing the wall to stay dry and never have issues with damp, rot or mould. This would be correct detailing, however, you would still have the issue of gaps in the framework.

Insulation

There is another issue with timber frame construction, and that is of the installation of insulation.

Rigid insulation will have gaps, as mentioned earlier. Gaps between the timber framing and the rigid insulation, albeit slight, will allow air movement.

Another insulation type is quilt insulation. This is a better thermal performer and sound absorber, but it is not rigid and will sag over time as the building settles, leaving large gaps at the top of the framing.

Rigid insulation fitted tightly with an air-tight membrane on the inside such as Pro-Clima’s ‘Intello’, would be a more satisfactory construction detail.

Structural Insulated Panels (SIPs)

SIPs always seem to be an “up and coming” building product. There are a few SIPs systems that work fantastically well, and there are many who try to create a simpler ‘one panel does all’ scenario. This is a contributing factor in SIPs' slower market growth in Australia, but awareness and education of SIPs panels is ever-increasing due to their high reputation internationally.

Traditional SIPs have a very steady stronghold in the building markets in the US, UK, Europe and Japan. Generally comprising of OSB (Orientated Strand Board) as both structural skins, with an insulated core, commonly PIR (Polyisocyanurate) or EPS (Expanded Polystyrene).

A cross-section of a SIPs Industries panel.

A cross-section of a SIPs Industries panel.

The SIPs building system can form Floors, Walls and Roofs and they are of various thicknesses of insulation. This means that the R-Rating varies between the thicknesses, but even the thinnest panel is quite good.

The system is similar to timber frame in that a breather membrane is applied to the external side, with a ventilated cavity to allow for vapour and moisture to ventilate away, and then cladding outside of this. Internally the finish is generally plasterboard directly fixed to the SIPs.

There are many advantages to using SIPs such as the speed of install (a single storey 4 bedroom home, walls and roof can be erected in under 5 days), the accuracy of dimensions (SIPs are almost millimetre perfect) and fitting of fixed furniture is a dream due to the straight and constant structural board.

But these are all secondary to the thermal performance of the structure. There are no gaps, very little thermal bridging and have been tested to be air-tight. This kind of construction can almost ensure that moisture is not travelling into the structure.

SIPs are generally the benchmark product for Passivhaus construction due to the ability to achieve air-tightness whilst maintaining a continuous thermally broken insulation layer.

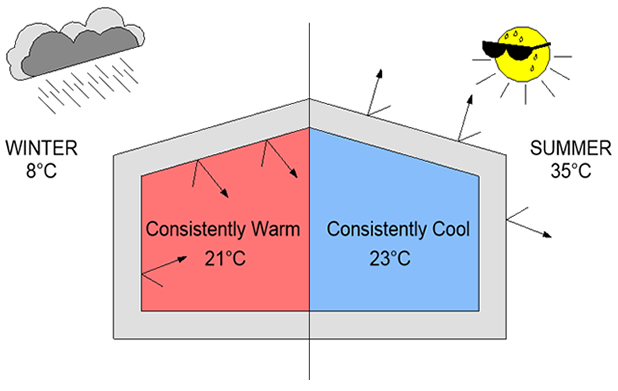

Comfort of living within a SIPs enveloped home is a noticeable environment. It is quiet as the acoustic performance of the air-tight building system keeps noise out, the ambient and consistent temperature throughout the building are maintained due to insulation and no draughts flow, which is a standout sensation.

And adding an Energy Recovery Unit (MHRV) means that constant fresh air is delivered into the building and is brought to the inside temperature by passing the outgoing stale and moist air within the unit mechanism. This saves dollars on energy and gets fresh air to the occupants and the building.

SIPs create a comfortable ambience all year round.

SIPs create a comfortable ambience all year round.

Contact SIPs Industries on (08) 9494 2211 for more information and to chat about the many benefits of building your home with SIPs.