Comparison: SIPs Vs Other Building Products - Part 3: Steel Frame

Everything stated in the previous article describing current timber framing construction in Australia is also relevant to Steel Framing.

Steel framing is a little worse however as every steel stud, being lightweight steel, is a conductor, a conductor which will quickly transfer energy through it.

Steel

The framing being at 600mm centres generally, will be cold in winter and as it is cold; there is a high chance that moisture in the air will condensate on the steel, and even just inside the steel on the plasterboard.

This means moisture is within the walls and will cause mould.

Energy is also being lost to the outside through the steel frame conducting the energy from inside to outside. As you heat or cool the building, the framing is transferring that energy away from the building.

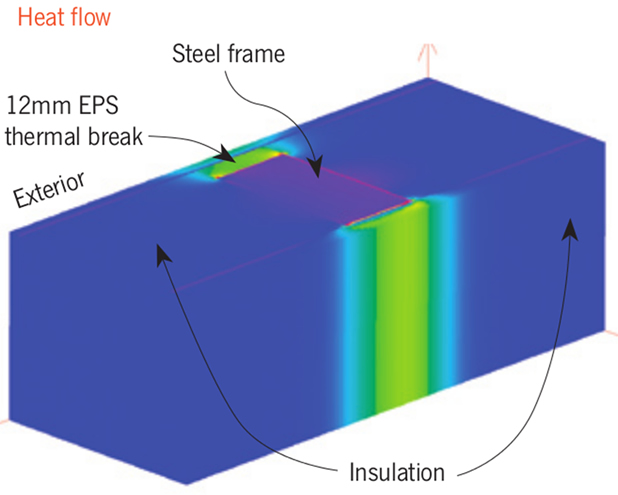

According to a Science Direct report from 2014, the thermal conduction of steel frames is 1000-1500 times higher than brick. The image Below will show the heat flow through the metal frame.

Thermal conduction from a steel frame.

Thermal conduction from a steel frame.

Structural Insulated Panels (SIPs)

SIPs always seem to be an “up and coming” building product. There are a few SIPs systems that work fantastically well, and there are many who try to create a simpler ‘one panel does all’ scenario. This is a contributing factor in SIPs' slower market growth in Australia, but awareness and education of SIPs panels is ever-increasing due to their high reputation internationally.

Traditional SIPs have a very steady stronghold in the building markets in the US, UK, Europe and Japan. Generally comprising of OSB (Orientated Strand Board) as both structural skins, with an insulated core, commonly PIR (Polyisocyanurate) or EPS (Expanded Polystyrene).

A cross-section of a SIPs Industries panel.

A cross-section of a SIPs Industries panel.

The SIPs building system can form Floors, Walls and Roofs and they are of various thicknesses of insulation. This means that the R-Rating varies between the thicknesses, but even the thinnest panel is quite good.

The system is similar to timber frame in that a breather membrane is applied to the external side, with a ventilated cavity to allow for vapour and moisture to ventilate away, and then cladding outside of this. Internally the finish is generally plasterboard directly fixed to the SIPs.

There are many advantages to using SIPs such as the speed of install (a single storey 4 bedroom home, walls and roof can be erected in under 5 days), the accuracy of dimensions (SIPs are almost millimetre perfect) and fitting of fixed furniture is a dream due to the straight and constant structural board.

But these are all secondary to the thermal performance of the structure. There are no gaps, very little thermal bridging and have been tested to be air-tight. This kind of construction can almost ensure that moisture is not travelling into the structure.

SIPs are generally the benchmark product for Passivhaus construction due to the ability to achieve air-tightness whilst maintaining a continuous thermally broken insulation layer.

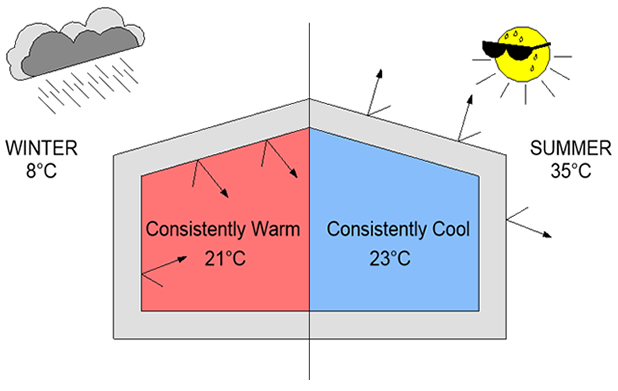

Comfort of living within a SIPs enveloped home is a noticeable environment. It is quiet as the acoustic performance of the air-tight building system keeps noise out, the ambient and consistent temperature throughout the building are maintained due to insulation and no draughts flow, which is a standout sensation.

And adding an Energy Recovery Unit (MHRV) means that constant fresh air is delivered into the building and is brought to the inside temperature by passing the outgoing stale and moist air within the unit mechanism. This saves dollars on energy and gets fresh air to the occupants and the building.

SIPs create a comfortable ambience all year round.

SIPs create a comfortable ambience all year round.

Contact SIPs Industries on (08) 9494 2211 for more information and to chat about the many benefits of building your home with SIPs.